Synchronous Motor:Hunting or Surging or Phase Swinging

Hunting or Surging or Phase Swinging

When a synchronous motor is used for driving a varying load, then a condition known as hunting is produced. Hunting may also be caused if supply frequency is pulsating (as in the case of genera- tors driven by reciprocating internal combustion engines).

We know that when a synchronous motor is loaded (such as punch presses, shears, compressors and pumps etc.), its rotor falls back in phase by the coupling angle a. As load is progressively increased, this angle also increases so as to produce more torque for coping with the increased load. If now, there is sudden decrease in the motor load, the motor is immediately pulled up or advanced to a new value of a corresponding to the new load. But in this process, the rotor overshoots and hence is again pulled back. In this way, the rotor starts oscillating (like a pendulum) about its new position of

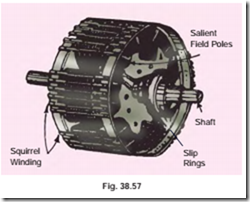

equilibrium corresponding to the new load. If the time period of these oscillations happens to be equal to the natural time period of the machine (refer Art. 37.36) then mechanical resonance is set up. The amplitude of these oscillations is built up to a large value and may eventually become so great as to throw the machine out of synchronism. To stop the build-up of these oscillations, dampers or damping grids (also known as squirrel-cage winding) are employed. These dampers consist of short- circuited Cu bars embedded in the faces of the field poles of the motor (Fig. 38.57). The oscillatory motion of the rotor sets up eddy currents in the dampers which flow in such a way as to suppress these oscillations.

But it should be clearly understood that dampers do not completely prevent hunting because their operation depends upon the presence of some oscillatory motion. Howover, they serve the additional purpose of making the synchronous motor self-starting.

Methods of Starting

As said above, almost all synchronous motors are equipped with dampers or squirrel cage windings consisting of Cu bars embedded in the pole-shoes and short-circuited at both ends. Such a motor starts readily, acting as an induction motor during the starting period. The procedure is as follows :

The line voltage is applied to the armature (stator) terminals and the field circuit is left unexcited. Motor starts as an induction motor and while it reaches nearly 95% of its synchronous speed, the d.c. field is excited. At that moment the stator and rotor poles get engaged or interlocked with each other and hence pull the motor into synchronism.

However, two points should be noted :

1. At the beginning, when voltage is applied, the rotor is stationary. The rotating field of the stator winding induces a very large e.m.f. in the rotor during the starting period, though the value of this e.m.f. goes on decreasing as the rotor gathers speed.

Normally, the field windings are meant for 110-V (or 250 V for large machines) but during starting period there are many thousands of volts induced in them. Hence, the rotor windings have to be highly insulated for with-standing such voltages.

2. When full line voltage is switched on to the armature at rest, a very large current, usually 5 to 7 times the full-load armature current is drawn by the motor. In some cases, this may not be objectionable but where it is, the applied voltage at starting, is reduced by using auto- transformers (Fig. 38.58). However, the voltage should not be reduced to a very low value because the starting torque of an induction motor varies approximately as the square of the applied voltage. Usually, a value of 50% to 80% of the full-line voltage is satisfactory.

Auto-transformer connections are shown in Fig. 38.58. For reducing the supply voltage, the switches S1 are closed and S2 are kept open. When the motor has been speeded-up, S2 are closed and S1 opened to cut out the transformers.

Comments

Post a Comment