Special machines:Servo motors

Servomotors

They are also called control motors and have high-torque capabilities. Unlike large industrial motors, they are not used for continuous energy conversion but only for precise speed and precise position control at high torques. Of course, their basic principle of operation is the same as that of other electromagnetic motors. However, their construction, design and mode of operation are different. Their power ratings vary from a fraction of a watt upto a few 100 W. Due to their low-inertia, they have high speed of response. That is why they are smaller in diameter but longer in length. They generally operate at vary low speeds or sometimes zero speed. They find wide applications in radar, tracking and guidance systems, process controllers, computers and machine tools. Both dc and a.c. (2-phase and 3-phase) servomotors are used at present.

Servomotors differ in application capabilities from large industrial motors in the following respects :

1. They produce high torque at all speeds including zero speed.

2. They are capable of holding a static (i.e. no motion) position.

3. They do not overheat at standstill or lower speeds.

4. Due to low-inertia, they are able to reverse directions quickly.

5. They are able to accelerate and deaccelerate quickly.

6. They are able to return to a given position time after time without any drift.

These motors look like the usual electric motors. Their main difference from industrial motors is that more electric wires come out of them for power as well as for control. The servomotor wires go to a controller and not to the electrical line through contactors. Usually, a tachometer (speed indicating device) is mechanically connected to the motor shaft. Sometimes, blower or fans may also be attached for motor cooling at low speeds.

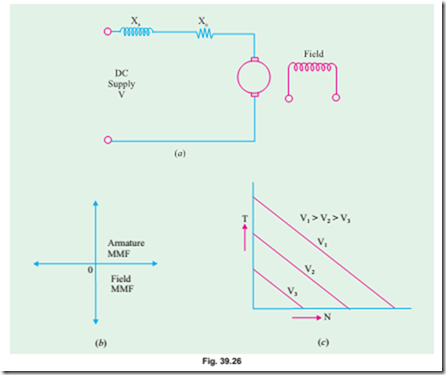

These motors are either separately-excited dc motors or permanent-magnet dc motors. The schematic diagram of a separately-excited d.c. motor alongwith its armature and field MMFs and torque/speed characteristics is shown in Fig. 39.26. The speed of d.c. servomotors is normally controlled by varying the armature voltage. Their armature is deliberately designed to have large resistance so that torque-speed characteristics are linear and have a large negative slope as shown in Fig. 39.26 (c). The negative slope serves the purpose of providing the viscous damping for the servo drive system.

As shown in Fig. 39.26 (b), the armature m.m.f. and excitation field mmf are in quadrature. This fact provides a fast torque response because torque and flux become decoupled. Accordingly, a step change in the armature voltage or current produces a quick change in the position or speed of the rotor.

Comments

Post a Comment