Single-phase motors:Shaded-pole Single-phase Motor

Shaded-pole Single-phase Motor

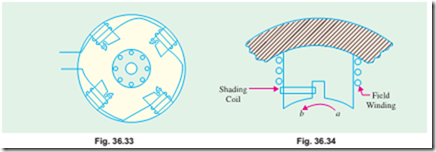

In such motors, the necessary phase-splitting is produced by induction. These motors have salient poles on the stator and a squirrel-cage type rotor Fig.

36.33 shows a four-pole motor with the field poles connected in series for alternate polarity. One pole of such a motor is shown separately in Fig. 36.34. The laminated pole has a slot cut across the laminations approximately one-third distance from one edge. Around the small part of the pole is placed a short- circuited Cu coil known as shading coil. This part of the pole is known as shaded part and the other as Shaded pole single phase motor unshaded part. When an alternating current is passed through the exciting (or field) winding surrounding the whole pole, the axis of the pole shifts from the unshaded part a to the shaded part b. This shifting of the magnetic axis is, in effect, equivalent to the actual physical movement of the pole. Hence, the rotor starts rotating in the direction of this shift i.e. from unshaded part to the shaded part.

Let us now discuss why shifting of the magnetic axis takes place. It is helpful to remember that the shading coil is highly inductive. When the alternating current through exciting coil tends to increase, it induces a current in the shading coil by transformer action in such a direction as to oppose its growth. Hence, flux density decreases in the shaded part when exciting current increases. However, flux density increases in the shaded part when exciting current starts decreasing (it being assumed that exciting current is sinusoidal).

In Fig. 36.35 (a) exciting current is rapidly increasing along OA (shown by dots). This will produce an e.m.f. in the shading coil. As shading coil is of low resistance, a large current will be set up in such a direction (according to Lenz’s law) as to oppose the rise of exciting current (which is responsible for its production). Hence, the flux mostly shifts to the unshaded part and the magnetic axis lies along the middle of this part i.e. along NC.

Next, consider the moment when exciting current is near its peak value i.e. from point A to B [Fig. 36.35 (b)]. Here, the change in exciting current is very slow. Hence, practically no voltage and, therefore, no current is induced in the shading coil. The flux produced by exciting current is at its maximum value and is uniformly distributed over the pole face. So the magnetic axis shifts to the centre of the pole i.e. along positions ND.

Fig. 36.35 (c) represents the condition when the exciting current is rapidly decreasing from B to C. This again sets up induced current in the shading coil by transformer action. This current will flow in such a direction as to oppose this decrease in exciting current, with the result that the flux is strengthened in the shaded part of the pole. Consequently, the magnetic axis shifts to the middle part of the shaded pole i.e. along NE.

From the above discussion we find that during the positive half-cycle of the exciting current, a N-pole shifts along the pole from the unshaded to the shaded part. During the next negative half- cycle of the exciting current, a S-pole trails along. The effect is as if a number of real poles were actually sweeping across the space from left to right.

Shaded pole motors are built commercially in very small sizes, varying approximately from 1/250 h.p. (3W) to 1/6 h.p. (125 W).

Although such motors are simple in construction, extremely rugged, reliable and cheap, they suffer from the disadvantages of (i) low starting torque (ii) very little overload capacity and (iii) low efficiency. Efficiencies vary from 5% (for tiny sizes) to 35 (for higher ratings). Because of its low starting torque, the shaded-pole motor is generally used for small fans, toys, instruments, hair dryers, ventilators, circulators and electric clocks. It is also frequently used for such devices as churns, phonograph turntables and advertising displays etc. The

direction of rotation of this motor cannot be changed, because it is fixed by the position of copper rings.

A typical torque / speed curve for such a motor is shown in Fig. 36.36.

Comments

Post a Comment