Single-phase motors:Repulsion Induction Motor

Repulsion Induction Motor

In the field of repulsion motor, this type is becoming very popular, because of its good all-round characteristics which are comparable to those of a compound d.c. motor. It is particularly suitable for those applications where the load can be removed entirely by de-clutching or by a loose pulley.

This motor is a combination of the repulsion and induction types and is sometimes referred to as squirrel-cage repulsion motor. It possesses the desirable characteristics of a repulsion motor and the constant-speed characteristics of an induction motor.

It has the usual stator winding as in all repulsion motors. But there are two separate and independent windings in the rotor (Fig. 36.41).

(i) a squirrel-cage winding and

(ii) commutated winding similar to that of a d.c. armature.

Both these windings function during the entire period of operation of the motor. The commutated winding lies in the outer slots while squirrel-cage winding is located in the inner slots*. At start, the commutated winding supplies most of the torque, the squirrel-cage winding being practically inactive because of its high reactance. When the rotor accelerates, the squirrel-cage winding takes up a larger portion of the load.

The brushes are short-circuited and ride on the commutator continuously. One of the advantages of this motor is that it requires no centrifugal short- circuiting mechanism. Sometimes such motors are also made with compensating winding for improving the power factor.

As shown in Fig. 36.42, its starting torque is high, being in excess of 300 per cent. Moreover, it has a fairly constant speed regulation. Its field of application includes house-hold refrigerators, garage air pumps, petrol pumps, compressors, machine tools, mixing machines, lifts and hoists etc.

Brushless d.c. seromotor

A.C. Series Motors

If an ordinary d.c. series motor were connected to an a.c. supply, it will rotate and exert unidirectional torque* because the current flowing both in the armature and field reverses at the same time. But the performance of such a motor will not be satisfactory for the following reasons :

1. the alternating flux would cause excessive eddy current loss in the yoke and field cores which will become extremely heated.

2. vicious sparking will occur at brushes because of the huge voltage and current induced in the short-circuited armature coils during their commutation period.

3. power factor is low because of high inductance of the field and armature circuits.

Induction type AC sevro motor and control box However, by proper modification of design and other refinements, a satisfactory single-phase motor has been produced.

The eddy current loss has been reduced by laminating the entire iron structure of the field cores and yoke.

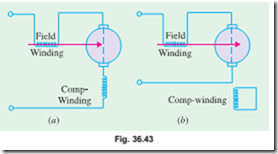

Power factor improvement is possible only by reducing the magnitudes of the reactances of the field and armature windings. Field reactance is reduced by reducing the number of turns on the field windings. For a given current, it will reduce the field m.m.f. which will result in reduced air- gap flux. This will tend to increase the speed but reduce motor torque. To obtain the same torque, it will now be necessary to increase the number of armature turns proportionately. This will, however, result in increased inductive reactance of the armature, so that the overall reactance of the motor will not be significantly decreased. Increased armature m.m.f. can be neutralized effectively by using a compensating winding. In conductively- compensated motors, the compensating winding is connected in series with the armature [Fig.36.43 (a)] whereas in inductively- compensated motors, the compensating winding is short- circuited and has no interconnection with the motor circuit [Fig. 36.43

(b)]. The compensating winding acts as a short-circuited secondary of a transformer, for which the armature winding acts as a primary. The current in the compensating winding will be proportional to the armature current and 180º out of phase with it.

Generally, all d.c. series motors are ‘provided’ with commutating poles for improving commutation (as in d.c. motors). But commutating poles alone will not produce satisfactory commutation, unless something is done to neutralize the huge voltage induced in the short-circuited armature coil by transformer action (this voltage is not there in d.c. series motor). It should be noted that in an a.c. series motor, the flux produced by the field winding is alternating and it induces voltage (by transformer action) in the short-circuited armature coil during its commutating period. The field winding, associated with the armature coil undergoing commutation, acts as primary and the armature coil during its commutating period acts as a short-circuited secondary. This transformer action produces heavy current in the armature coil as it passes through its commutating period and results in vicious sparking, unless the transformer voltage is neutralized. One method, which is often used for large motors, consists of shunting the winding of each commutating pole with a non-inductive resistance, as shown in Fig. 36.44 (a).

Fig. 36.44. (b) shows the vector diagram of a shunted commutator pole. The current Ic through the commutating pole (which lags the total motor current) can be resolved into two rectangular com- ponents Id and Iq as shown. Id produces a flux which is in phase with total motor current I whereas flux produced by Iq lags I by 90º. By proper adjustment of shunt resistance (and hence Is), the speed voltage generated in a short-circuited coil by the cutting of the 90º lagging component of the commutating pole flux may be made to neutralize the voltage induced by transformer action.

Comments

Post a Comment