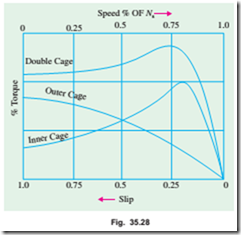

Computations and circle diagrams:Starting of Induction Motors

Starting of Induction Motors It has been shown earlier that a plain induction motor is similar in action to a polyphase transformer with a short-circuited rotating secondary. Therefore, if normal supply voltage is applied to the stationary motor, then, as in the case of a transformer, a very large initial current is taken by the primary, at least, for a short while. It would be remembered that exactly similar conditions exist in the case of a d.c. motor, if it is thrown directly across the supply lines, because at the time of starting it, there is no back to oppose the initial inrush of current. Induction motors, when direct-switched, take five to seven times their full-load current and develop only 1.5 to 2.5 times their full-load torque. This initial excessive current is objectionable because it will produce large line-voltage drop that, in turn, will affect the operation of other electrical equipment connected to the same lines. Hence, it is not advisable to line-start motors of...