CLASSIFICATION OF DC MACHINES part1

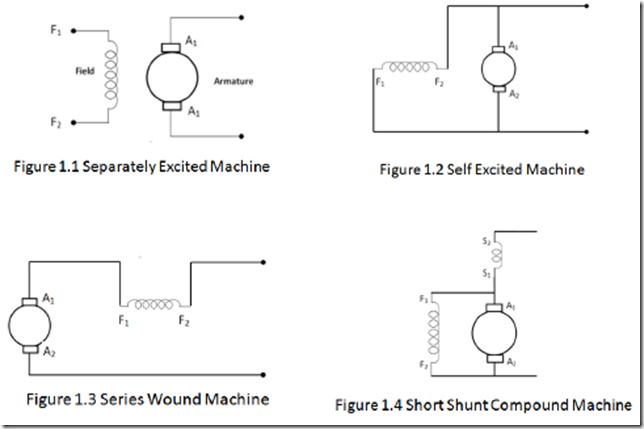

METHODS OF EXCITATION: depending on the type of excitation of field winding, there are two basic types of DC machine.

1. Separately excited machine: In this type of machines the field flux is produced by connecting the field winding to an external source.

2. Self excited machine: The field flux is produced by connecting the field winding with the armature in this type. A self excited machine requires residual magnetism for operation.

Depending on the type of field winding connection DC machines can be further classified as:

1. Shunt machine: The field winding consisting of large number of turns of thin wire is usually excited in parallel with armature circuit and hence the nameshunt field winding. This winding will be having more resistance and hence carries less current.

2. Series machine: The field winding has a few turns of thick wire and is connected in series with armature.

3. Compound machine: Compound wound machine comprises of both series and shunt windings and can be either short shunt or long shunt, cumulative, differential or flat compounded.

In separate excited DC machine, the field winding is connected to a separate DC source. This type of machine is most flexible as full and independent control of both armature and field circuit is possible. Figure 1.1 shows separately excited DC generator. Permanent magnet machines also fall in this category.

A self excited DC generator could be excited by its armature voltage as shown in figure 1.2 (i.e., shunt excitation) or by its armature current as shown in figure 1.3 (series excitation). Compound wound generator comprises of both series and shunt windings and can be either short shunt (figure 1.4) or long shunt (figure 1.5), cumulative or differential or flat compounded.

ARMATURE WINDINGS

Armature winding is an arrangement of conductors distributed in slots provided on the periphery of the armature. Depending on the way in which the coils are interconnected at the commutator end of the armature, the windings can be classified as lap and wave windings. Further they can be classified as simplex and multiplex. The important terms used in armature windings are given below:

COIL PITCH/COIL SPAN: represents the span of the coil. It can be represented in terms of electrical degrees, slots or conductor. For full pitched winding, the span is 1800 electrical or number of slots per pole. A full pitched coil leads to maximum voltage per coil.

BACK PITCH/COIL SPAN(Yb): is the distance measured in between the two coil sides of the same coil at the back end of the armature, the commutator end being the front end of armature. It can be represented in terms of number of slots or coil sides. Back pitch also

COMMUTATOR PITCH (YC): is measured in terms of commutator segments between the two coil ends of a coil.

SINGLE LAYER WINDING: In this winding one coil is placed in each slot.

DOUBLE LAYER WINDING: In this winding two or multiples of coil sides are arranged in two layers in each slot.

Front pitch, back pitch and commutator pitch are shown in figures 1.7 and 1.8 for lap and wave windings respectively.

SALIENT FEATURES OF LAP AND WAVE WINDING

1. Armature winding is a closed winding. Depending on the type of winding, the closed path gets divided into number of parallel paths and is available between the positive and negative brushes.

2. Wave winding is used for high voltage low current machines.

3. Equalizing rings are not required in wave winding where as there are used in lap winding.

4. Lap winding is suitable for low voltage high current machines because of more number of parallel paths.

In case of lap winding, the number of parallel path (A) = number of poles (P)

In case of wave winding, the number of parallel path (A) = 2 irrespective of number of poles.

Each path will have Z/A conductors connected in series.

EQUATION FOR INDUCED EMF:

Let Φ= flux per pole in weber

Comments

Post a Comment